At RAIN, it is our continuous pursuit to achieve resource efficiency and carbon productivity. In our Carbon segment, we create value‑added materials such as calcined petroleum coke (CPC) and coal tar pitch (CTP) that are key raw materials in countless products and manufacturing processes.

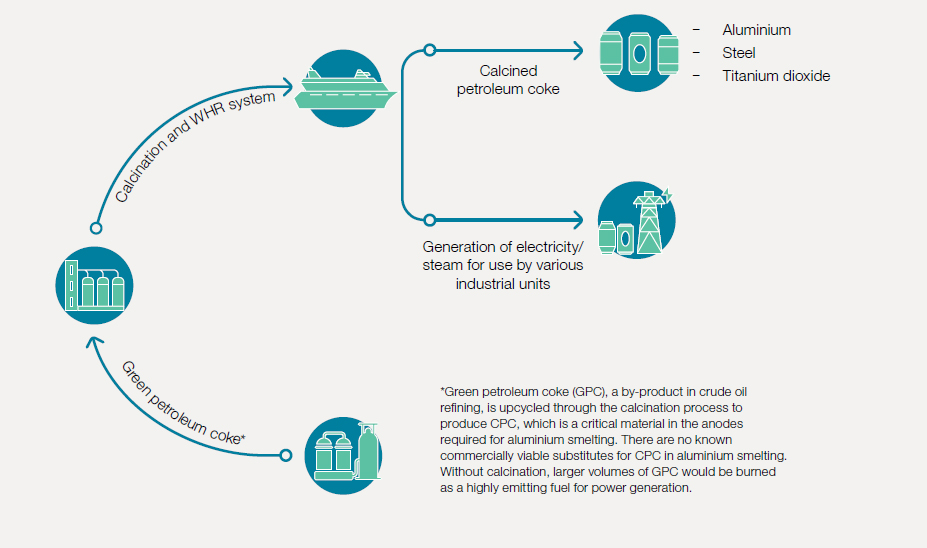

Calcination

Green petroleum coke (GPC), the raw material for CPC, is a by-product of oil refining. The CPC produced by our calcination facilities in India and the US is an essential raw material for making the anodes required for aluminium smelting. Without CPC, aluminium smelters cannot produce this infinitely recyclable, strong, lightweight and versatile metal. Our ability to upcycle GPC also prevents it from being burned as a low-cost, high CO2-emitting fuel for electricity production and enables us to make more productive use of the carbon.

Beyond aluminium, our CPC is an important raw material in the production of titanium dioxide, which is used as the base pigment for paints for construction and automotive applications. TiO2 also is used as a filler in plastics, coatings, cosmetics, toothpaste and sunscreen. Elsewhere, our CPC is used to produce high-strength steel for building bridges, skyscrapers and other infrastructure.

Our proprietary anhydrous carbon pellets (ACP) are another example of how we are leveraging innovation to upcycle industrial by‑products into value-added materials with environmental benefits. Once commercially available, our calcined ACP will be used in the production of anodes, which should reduce the energy consumption and emissions of aluminium smelters. It will also allow us to increase our GPC utilisation rate, since ACP facilitates the productive use of the fine particles in the raw material that are not recovered as product during the calcination process.

Calcination upcycling value chain

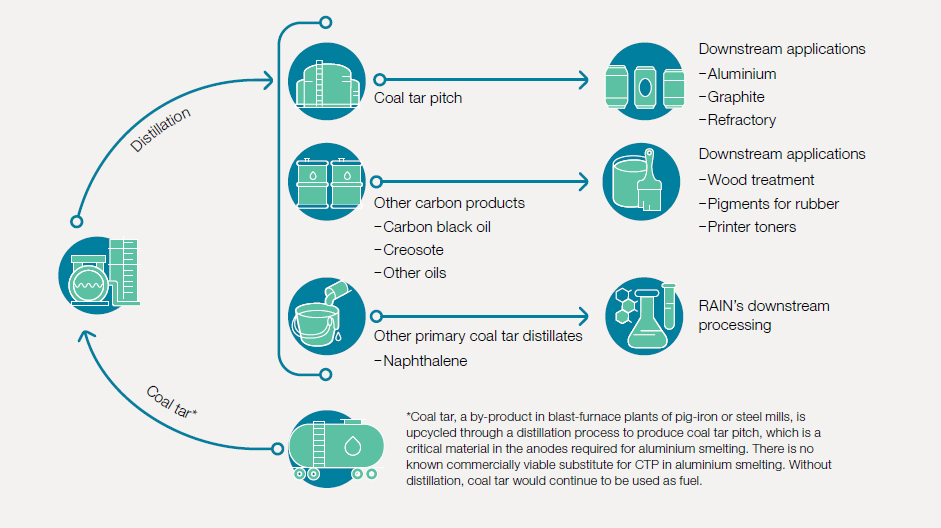

Distillation

Coal tar is another industrial by‑product that we upcycle through distillation. It is derived from the conversion of coal into metallurgical coke used for pig iron and steel production. Without distillation, coal tar would be burned as a fuel or disposed of as a hazardous waste.

Our ability to distil coal tar into coal tar pitch and other carbon products facilitates the creation of a range of value‑added materials that contribute to more sustainable and environment‑friendly end uses:

Lightweight and recyclable aluminium

Scrap recovery, a low-CO2 production process for steel

Creosote for wood treatment and preservation

Distillation upcycling value chain